Systems & Components

The proprietary push-pull pickling technology developed and operated by Samuel Nelson Technology offers the flexibility, capacity, and quality necessary to meet the stringent standards of the automotive industry.

Our team will work with you to diligently assess your specific needs and design customized pickling processes and equipment which deliver optimized performance and efficiency while minimizing emissions and consumables. In addition to supplying you with new pickling line equipment, we also can evaluate and replace existing equipment with the latest technology.

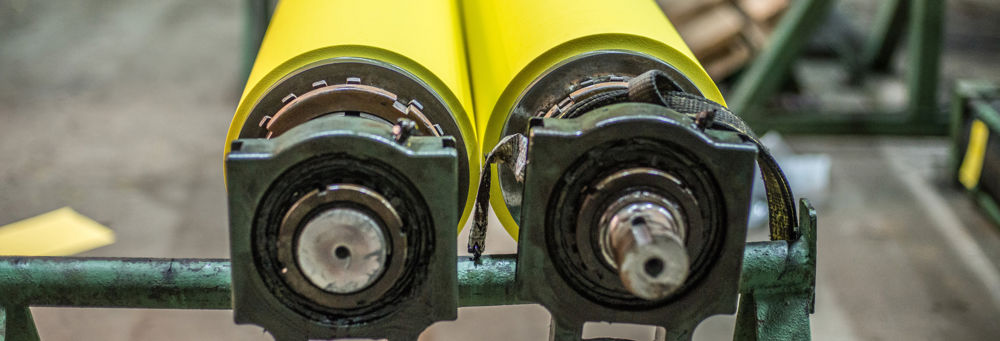

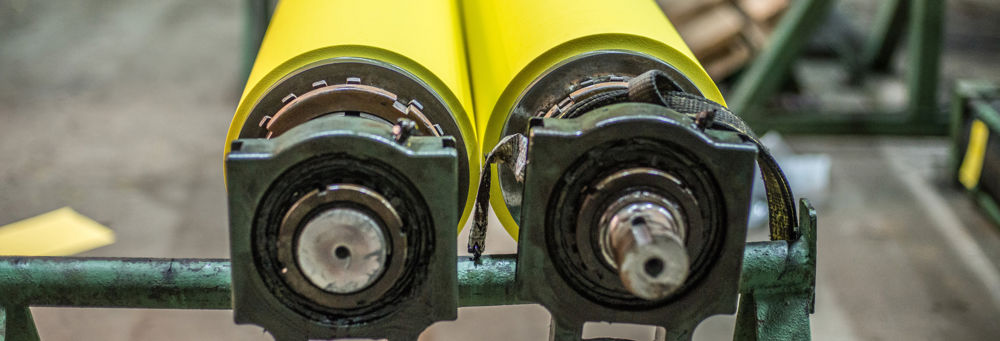

Pickling Process

Samuel Nelson Technology’s renowned Turbo-Tunnel pickle tank provides the most efficient turbulent pickling system. This unique system creates a high amount of turbulence around the strip, increasing the rate at which the scale is removed. The Turbo-Tunnel cover system reduces evaporation and thus energy required to heat the hydrochloric acid compared to a typical pickle tank. The cover system also creates a better working environment and lowers building maintenance costs.

Depending on your production profile and annual capacity, the pickling process can be designed in many different configurations while utilizing the Turbo-Tunnel tank design. Whether you need a push-pull, semi-continuous or continuous pickling line, Samuel Nelson Technology has a solution for you.

Rinse Process

Whatever your circumstances, Samuel Nelson Technology has a rinse tank systems to suit your needs and can also provide a system which can decrease water usage, minimize the risk of staining during line stoppage, or both. Along with traditional spray rinse systems, Samuel Nelson Technology has designed a flooded rinse system which allows the strip to stop up to three times longer than a spray tank before rejectable staining occurs.

Fume Exhaust System

We’re often been told by customers that our pickling line environment does not resemble a typical pickling line! This is primarily due to the design of the fume exhaust system which collects, scrubs, and vents the hydrochloric acid fumes from the plant. Our fume systems go above and beyond environmental regulations for emissions and indoor air quality, ensuring that the health and wellbeing of your employees and building are protected from corrosion at all times.

Water Treatment Systems

Whatever your needs, Samuel Nelson Technology has solutions to effectively treat rinse water effluent on a once-through basis or to be recycled and reused in the Rinse process.

Pickling Facility Consulting

As pickling line owners and operators, Samuel Nelson Technology designs and builds not just process equipment but also complete pickling facilities. This means we can support our customers by providing all of the necessities around the core pickling equipment, from the plant layout to the details of the boiler room and everything in between. Learn more about our Consulting Services.