Burloak Technologies Inc. announced today it has been selected by MDA Space Ltd. (TSX:MDA), a leading provider of advanced technology and services to the rapidly expanding global space industry, as part of the company’s supply chain for MDA AURORATM, a game-changing product line driving the transition from analog to digital satellite technology.

Burloak Technologies Inc., a division of Samuel, Son & Co., Limited, today announced that its Camarillo, California additive manufacturing facility has been certified to the AS9100 standard.

Additive manufacturing (AM) offers a number of advantages over traditional manufacturing, including shorter development cycles and stronger parts, but did you know AM is also better for the planet? In this installment of AM Hub, Arash Bazrafshan, Director of Business Development at Burloak Technologies, discusses the many environmental benefits of AM.

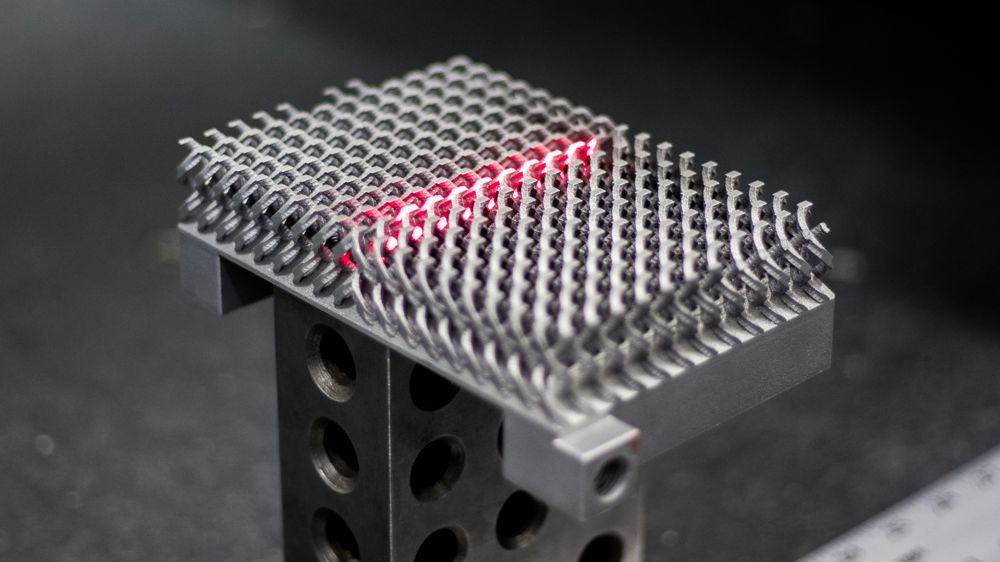

Burloak Technologies Inc., a division of Samuel, Son & Co., Limited, announced that it has been approved by The Boeing Company to inspect additively manufactured (AM) aluminum alloy components to Boeing’s BSS7046 specification using X-Ray Computed Tomography.

The event will provide the unique opportunity for attendees to examine key issues and opportunities within the US-domestic and international space industry, with a diverse variety of both industry and technological high-impact sessions.

Burloak Technologies is proud to deliver the highest quality AM solutions to our customers. Our team is celebrating the accreditation of our Oakville Materials Testing Lab to the ISO 17025 standard which outlines general requirements for the competence of testing and calibration laboratories.

Few industries have evolved as significantly as the space sector over the past decade, and AM has an important role to play in its future.

Like most companies supporting the aviation sector today, Burloak Technologies is seeking out new ways to enhance the sector’s sustainability – with a goal to help reduce the impact of air travel on the environment.

The four-day event will unite the global satellite and space communities for high-impact talks on the latest innovations and projects.

This development enables new opportunities to develop and produce aluminum Laser Powder Bed Fusion (LPBF) components with properties that cannot be achieved with traditional AM aluminum alloys.