Market Solutions

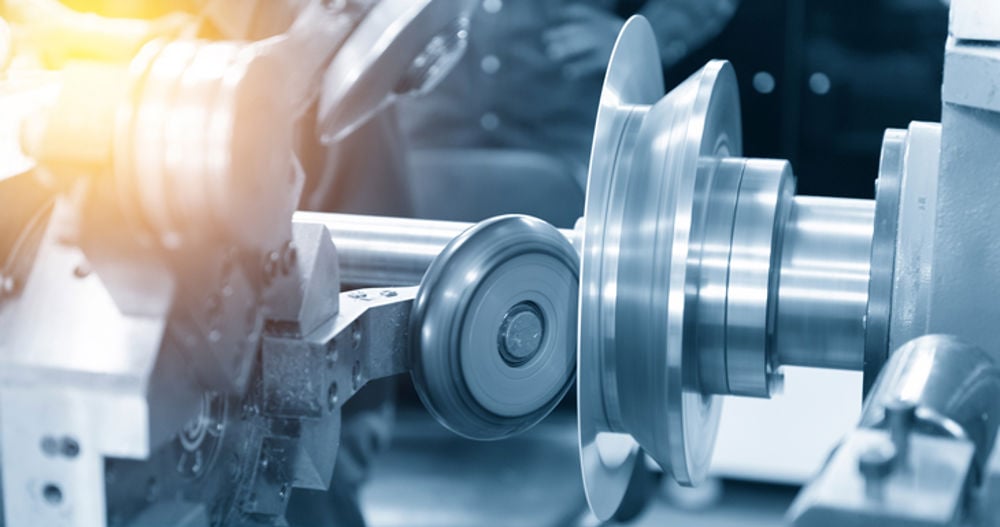

Metal Spinners serves a number of different markets including; Air Handling, Agriculture, HVAC, Oil & Gas, Power Transmission and many more.

We’re a leading metal-forming, manufacturing and service company devoted to providing our customers industry-leading metal spinning, hydroforming and other specialized metal-forming services. We form steel, stainless steel, cold-rolled steel, hot rolled steel, aluminum, copper, brass, hastelloy and inconel into a variety of shapes, including panels, hemispheres, hoppers, venturis, cans, pans, shells and other formed metal parts.