SAMUEL METAL SPINNERS

CONTACT US TO LEARN MORE ABOUT OUR METAL SPINNING SERVICES

We are a leading metal-forming, manufacturing and service company devoted to providing our customers industry-leading metal spinning, hydroforming and other specialized metal-forming services. Contact us today to learn more about our forming capabilities and services.

MATERIALS WE FORM:

Steel

Cold Rolled Steel

Hot Rolled Steel

Aluminum

Copper

Brass

Hastelloy

SHAPES WE FORM:

Panels

Hemispheres

Hoppers

Venturis

Cans

Pans

Shells

Other Formed Metal Parts

CAPABILITIES & SERVICES

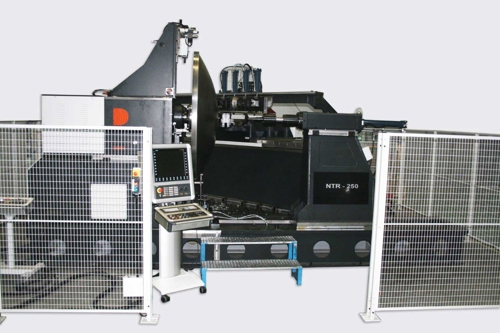

CNC Controlled Spinning

Our recent investments in computer controlled automatic lathes has allowed us to make components with greater consistency, tighter tolerances at a lower cost. Samuels’ investment in these machines has added to the strategy of providing your critical components more quickly and, coupled to investments in laser, welding and washing, allow us to provide completed parts without the need for added outside fabrication or internal value added operations.

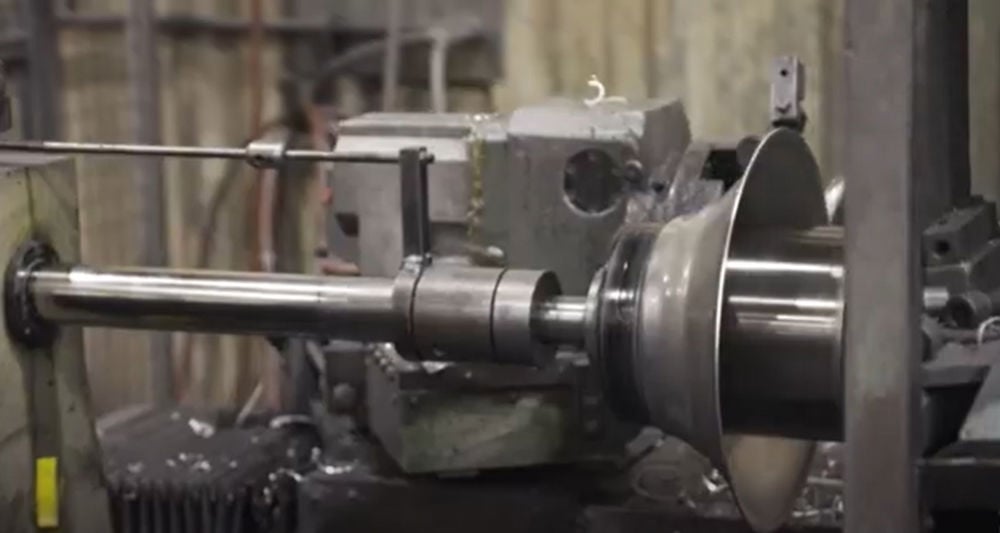

Heavy Duty Automated Spinning

In addition to our investment in automatic lathes, we reinforce our dedication to making the large, complex and difficult designs with the addition of another large auto lathe. This machine allows for part diameters to 100” with lengths to 70” while allowing us to form all gauges and grades of sheet metal including stainless, titanium, Hastelloy, aluminum, Inconel and mild steels. These machines provide consistent parts at tighter tolerances than past technologies or manual spinning ever allowed in the past.

Parts Washer

To complete your project, not only can we final trim and fabricate on our 5-axis laser, but we can also provide you with items ready for paint, or packaged for cross shipment to your final customers. Our parts washer uses a combination of ultrasonic and liquid wash to clean off mill oils, lubricants, metal shavings and other contaminants so that you are ready to apply your finish or have us finish box the parts to go into spare parts inventory immediately.