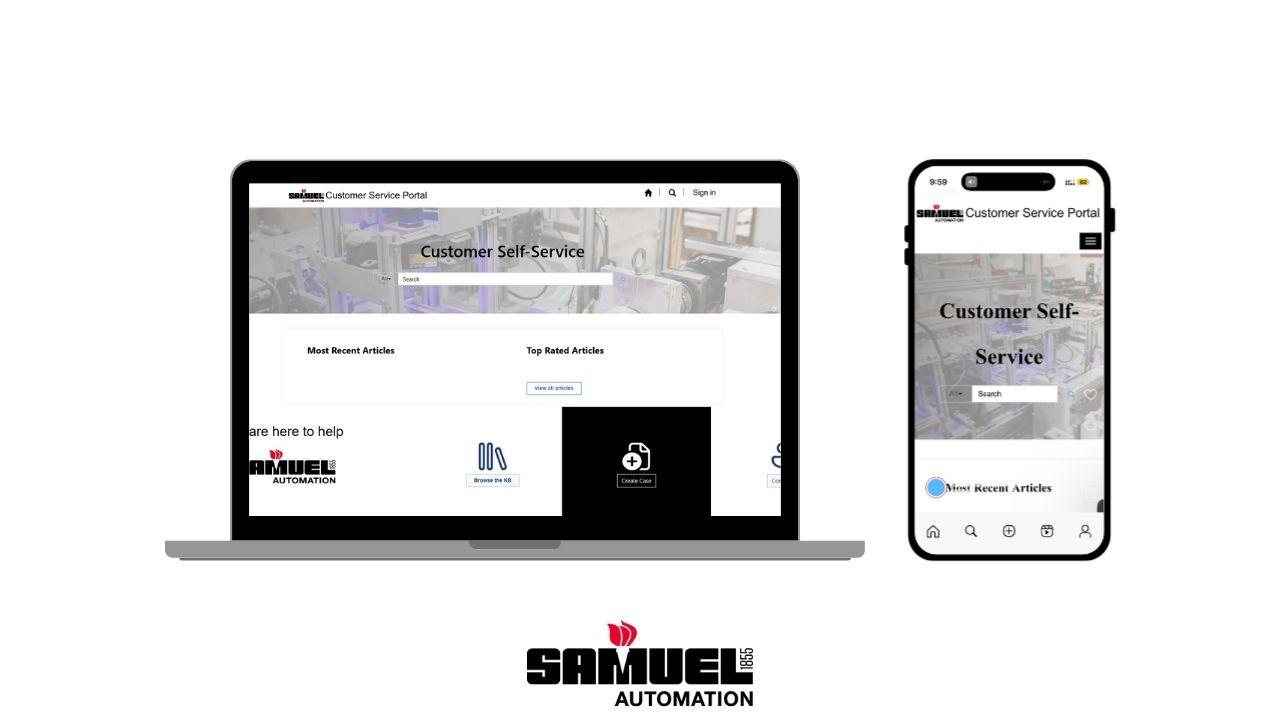

Samuel Automation Launches Customer Service Portal

Today, Samuel Automation officially launched their customer Service Portal, an online system specifically designed to make partnering with us even easier, by giving customers quick access to their support history and service records, so all the information they need can be found easily, in one place, when they need it most.